What is PEEK?

PEEK (polyetheretherketone) is a high-performance engineering thermoplastic that belongs to the polyaryletherketone family. Its molecular main chain contains linear aromatic polymer compounds with the following links. It is a semi-crystalline, thermoplastic special engineering plastic with excellent comprehensive properties such as high temperature resistance, self-lubrication, corrosion resistance, flame retardancy, hydrolysis resistance, wear resistance and fatigue resistance. It was initially used in the field of national defense and military industry, and then gradually expanded to the civilian field, including industrial manufacturing, aerospace, automobile industry, electronic and electrical and medical equipment. With the continuous improvement of PEEK synthesis and processing technology, its application fields have been broadened by high-performance materials obtained through chemical modification, blending, composite filling, etc.

PEEK Plastic Properties

Let’s explore its characteristics to better help you understand the performance of PEEK plastic. The main Properties of PEEK plastic include:

High temperature resistance

PEEK material has excellent high temperature resistance and can maintain stable performance in high temperature environments. It can withstand short-term operating temperatures up to 300°C and high temperatures of 250°C for continuous use. This means that in high-temperature environments, such as during manufacturing or use, PEEK materials are able to maintain their physical and chemical properties without deformation or decomposition. This is very beneficial for applications that require working in high temperature environments for long periods of time. This is one of the main reasons why PEEK materials are often used to replace metal parts.

Mechanical strength and hardness

PEEK material has high strength and hardness, which allows it to withstand greater pressure and wear. In applications that need to withstand greater stress, such as mechanical parts, wear-resistant parts, etc., PEEK materials can provide excellent mechanical properties. At the same time, its hardness also makes it excellent in applications that require wear resistance.

Chemical corrosion resistance

PEEK material is very resistant to most chemicals. This means that in applications that come into contact with chemical substances, such as chemical equipment, pharmaceutical equipment, etc., PEEK materials can resist the erosion of chemical substances and maintain stable performance.

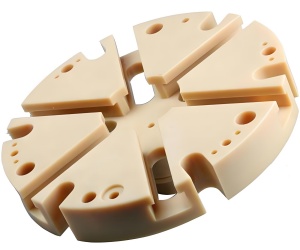

Wear resistance

PEEK material has excellent wear resistance and can resist friction and wear. In applications that need to withstand friction, such as bearings, gears, etc., PEEK materials can provide excellent wear resistance and extend the service life of the equipment.

Flame retardancy

PEEK material is self-extinguishing and can resist the spread of flames. This means that in applications that require fire protection, such as electronic equipment, automotive parts, etc., PEEK materials can provide good flame retardant properties and reduce the risk of fire.

Electrical insulation

PEEK material has good electrical insulation properties and can resist electric shock and sparks. In applications that require insulation, such as electronic components, power equipment, etc., PEEK materials can provide excellent electrical insulation properties to ensure the safe operation of equipment.

Fatigue resistance

PEEK material has excellent fatigue resistance and can resist repeated stress changes and fatigue fracture. In applications that need to withstand fatigue stress, such as springs, bearings, etc., PEEK materials can provide good fatigue resistance and extend the service life of the equipment.

Radiation resistance

PEEK material can resist high-energy radiation and has good radiation resistance. In applications that need to withstand radiation, such as the nuclear industry, medical equipment, etc., PEEK materials can provide good radiation resistance to ensure the normal operation of the equipment.

Biocompatibility

PEEK material has good compatibility with biological tissues. In the field of medical devices, PEEK materials are compatible with human tissues and will not cause adverse reactions. This makes PEEK materials widely used in the field of medical devices.

Self-lubricating

PEEK material has excellent self-lubricating properties, which means it can reduce friction and wear with other materials without additional lubricants. Especially those applications that require reducing friction and wear to improve efficiency and durability. This feature makes PEEK excellent in the field of bearings and has a wide range of applications.

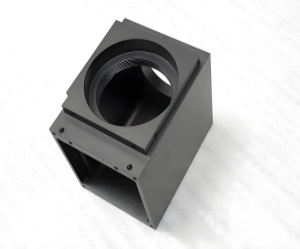

Processability

PEEK material has good processing properties and can be processed through injection molding, extrusion, compression molding, and other processes. This allows PEEK materials to be easily processed and shaped during production. At the same time, its processing properties also enable PEEK materials to meet the needs of various complex shapes and applications.