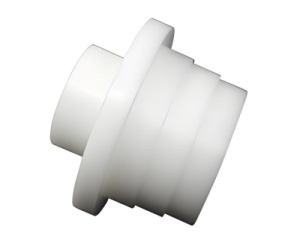

Plastic machining parts PEEK POM PTFE HDPE PA PC ABS

Plastic Machining Parts: Precision Crafted for Diverse Applications

Plastic machining parts have become an integral part of modern manufacturing, offering precise and customizable solutions for a wide range of industries. These parts are crafted through advanced machining processes that ensure accuracy, quality, and functionality.

The process of plastic machining involves transforming raw plastic materials into complex and highly accurate components. This is achieved using specialized tools and techniques that allow for the creation of intricate geometries and tight tolerances. The result is a part that precisely fits the requirements of the intended application.

One of the key advantages of plastic machining parts is the wide variety of plastic materials available. From common polymers like ABS and nylon to more advanced engineering plastics such as PEEK and Ultem, manufacturers can select the material that best suits the specific properties needed for the part. This includes considerations like strength, heat resistance, chemical resistance, and electrical insulation.

Plastic machining parts are widely used in the aerospace industry. They can be found in lightweight components for aircraft interiors, as well as in critical parts that require specific mechanical and thermal properties. In the automotive sector, they contribute to the production of interior trim, engine components, and electrical housings.

The medical field also benefits from plastic machining parts. Precision-made parts for medical devices, surgical instruments, and implants are often crafted from plastic due to its biocompatibility and the ability to meet strict hygiene standards.

In the electronics industry, plastic machining is used to create parts for enclosures, connectors, and insulators. The ability to achieve precise dimensions and smooth surfaces is crucial for ensuring proper fit and functionality.

Furthermore, plastic machining allows for rapid prototyping. This enables designers and engineers to quickly test and refine their concepts before moving on to full-scale production. It helps to reduce development time and costs, and ensures that the final product meets all design specifications.

The quality control in plastic machining is of paramount importance. Advanced measurement tools and inspection techniques are employed to ensure that each part meets the highest standards of accuracy and performance. This helps to minimize defects and ensure consistent quality across production runs.

Our plastic machining services are dedicated to providing you with top-quality parts that meet your exact needs. Our experienced team, state-of-the-art equipment, and strict quality management system guarantee that you receive products that are reliable and perform flawlessly in your applications.

Whether you need a small batch of custom parts or large-scale production, we have the capabilities and expertise to deliver.

Contact us to discuss your plastic machining part requirements and let us turn your ideas into reality.

Follow us on YouTube for the latest updates and insights.

Links

Send RFQ

Used industry