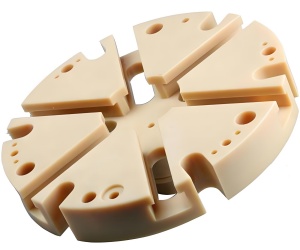

PEEK plastic turning CNC milling parts PEEK POM PTFE PA PE HDPE PC ABS, peek gears

PEEK Plastic Parts: The Ultimate Choice for High-Performance Applications

PEEK (Polyetheretherketone) plastic parts have gained significant popularity in various industries due to their exceptional properties and superior performance. These advanced components offer a unique combination of strength, heat resistance, chemical resistance, and low friction, making them an ideal choice for demanding applications.

One of the standout features of PEEK plastic parts is their remarkable mechanical strength. They can withstand high loads and stresses without deforming or failing, making them suitable for use in heavy-duty machinery and equipment. Their tensile strength and flexural modulus are comparable to some metals, yet they offer the advantage of being lightweight.

The heat resistance of PEEK is truly outstanding. It can withstand continuous operating temperatures of up to 260°C and intermittent temperatures even higher. This makes PEEK plastic parts ideal for applications in the aerospace, automotive, and electronics industries where components are exposed to high temperatures.

Chemical resistance is another key attribute of PEEK. It is resistant to a wide range of aggressive chemicals, including acids, bases, and organic solvents. This property makes PEEK parts suitable for use in the chemical processing, oil and gas, and medical fields, where exposure to corrosive substances is common.

PEEK plastic parts also exhibit low friction and excellent wear resistance. This makes them ideal for applications such as bearings, gears, and seals, where smooth operation and long service life are crucial. Their self-lubricating properties reduce the need for additional lubricants, simplifying maintenance and reducing the risk of contamination.

In the medical industry, PEEK is highly regarded for its biocompatibility. It is used in the manufacture of implants, surgical instruments, and prosthetics due to its ability to interact safely with the human body.

The manufacturing process of PEEK plastic parts is highly precise and customizable. Techniques such as injection molding and machining can be used to produce complex shapes and tight tolerances, ensuring that the parts meet the exact specifications of the application.

Our PEEK plastic parts are produced using the highest quality materials and state-of-the-art manufacturing processes. We are committed to providing our customers with products that not only meet but exceed their expectations in terms of performance and reliability.

Whether you are involved in aerospace engineering, automotive design, medical device manufacturing, or any other industry that requires high-performance components, our PEEK plastic parts are the solution you’ve been looking for.

Contact us to discuss your specific needs and let us help you find the perfect PEEK plastic parts for your application.

Follow us on YouTube for the latest updates and insights.

Links:

Contact us

Used industry