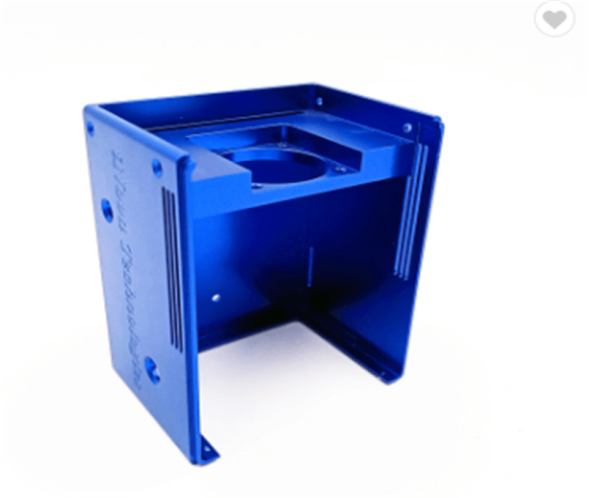

CNC milling parts aluminum anodizing plus sand blasting,colored anodizing aluminum parts

Anodized Aluminum Parts: Precision and Durability Combined

Anodized aluminum parts have emerged as a preferred choice in various industries, offering a unique blend of functionality, aesthetics, and longevity. These parts are not only visually appealing but also possess mechanical properties that make them highly suitable for a wide range of applications.

The anodizing process is a key factor that enhances the performance and appeal of aluminum parts. It involves creating an oxide layer on the surface of the aluminum, which provides several benefits. Firstly, it increases the hardness of the material, making it more resistant to scratches and abrasions. This is particularly important in applications where the parts are subject to frequent handling or contact with other surfaces. Secondly, the anodized layer offers excellent corrosion resistance, protecting the underlying aluminum from environmental factors such as moisture and chemicals. This makes anodized aluminum parts ideal for use in outdoor or harsh industrial environments.

One of the significant advantages of anodized aluminum parts is their lightweight nature. Aluminum is already a lightweight metal, and the anodizing process does not add significant weight. This makes them suitable for applications where weight reduction is crucial, such as in the aerospace and automotive industries. At the same time, they retain the strength and durability necessary to perform reliably in demanding conditions.

The aesthetic appeal of anodized aluminum parts cannot be overlooked. The process allows for a wide range of colors and finishes, from a classic matte look to a high-gloss shine. This gives designers and manufacturers the flexibility to create visually striking products that stand out in the market. Whether it’s for consumer electronics with a sleek and modern appearance or architectural components that add a touch of elegance, anodized aluminum parts offer endless possibilities for customization.

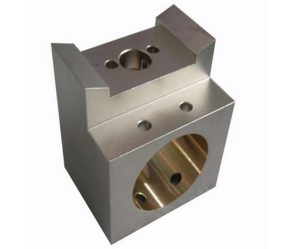

In terms of manufacturing, anodized aluminum parts can be produced with high precision. Computer Numerical Control (CNC) machining techniques can be employed to achieve complex geometries and tight tolerances, ensuring that the parts fit perfectly within the intended assembly. This level of precision is essential in industries where accuracy and functionality are paramount, such as in the production of medical devices and precision instruments.

Anodized aluminum parts also have excellent thermal conductivity. This property makes them suitable for applications where heat dissipation is a concern, such as in electronic devices and heat exchangers. The ability to efficiently transfer heat helps to improve the performance and reliability of the overall system.

In the aerospace industry, anodized aluminum parts are used in aircraft structures, engine components, and interior fittings. Their lightweight and corrosion-resistant properties contribute to fuel efficiency and the longevity of the aircraft. In the automotive sector, they can be found in engine parts, suspension components, and exterior trim, enhancing both performance and style.

For consumer electronics, anodized aluminum cases and housings provide a durable and stylish enclosure for devices like laptops, smartphones, and tablets. The ability to resist fingerprints and smudges while maintaining a premium look makes them highly desirable.

Architectural applications include window frames, door handles, and façade elements. The anodized finish not only looks attractive but also withstands the elements over time, maintaining the integrity of the building’s appearance.

In the medical field, anodized aluminum parts are used in surgical instruments, equipment, and implants due to their biocompatibility and sterilizability.

Our company is dedicated to providing high-quality anodized aluminum parts that meet the strictest industry standards. We employ state-of-the-art manufacturing processes and quality control measures to ensure that each part is flawless. Our team of experts works closely with clients to understand their specific requirements and offer customized solutions that exceed expectations.

Contact us to discuss your anodized aluminum parts needs and let us help you bring your projects to life.

Follow us on YouTube for the latest updates and insights.

Links:

Contact Us

Used industry